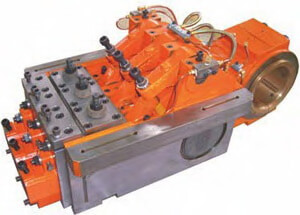

3 STATION BOLT FORMER BF-SERIES

- Features

- Specification

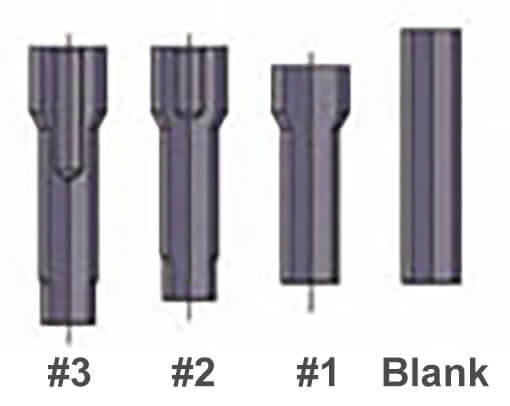

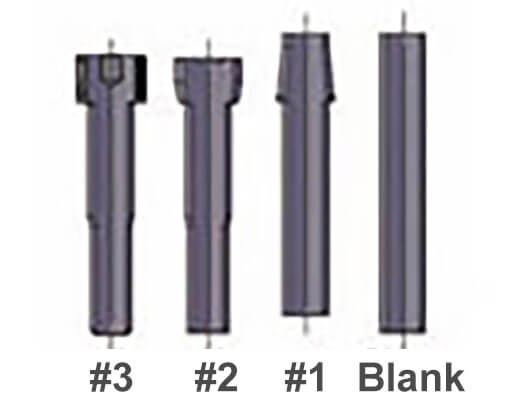

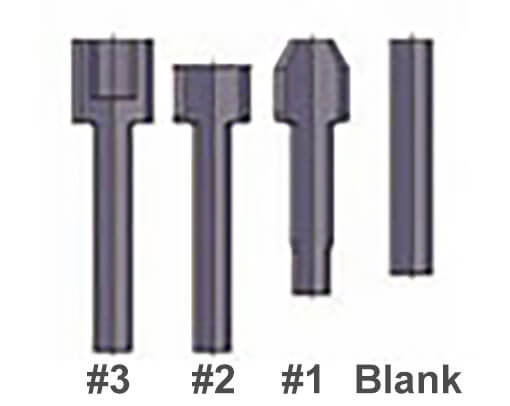

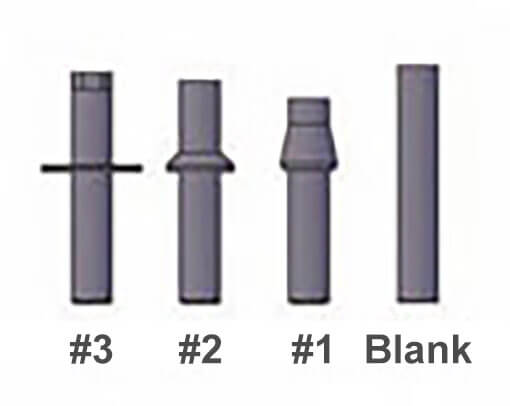

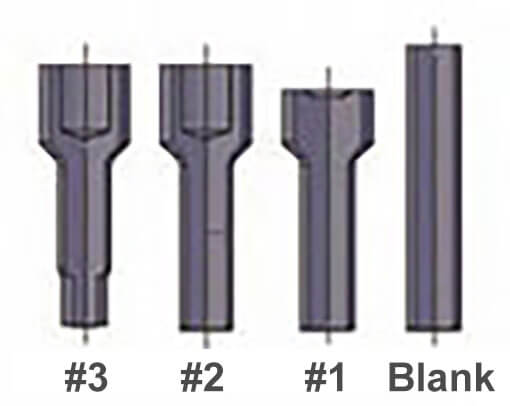

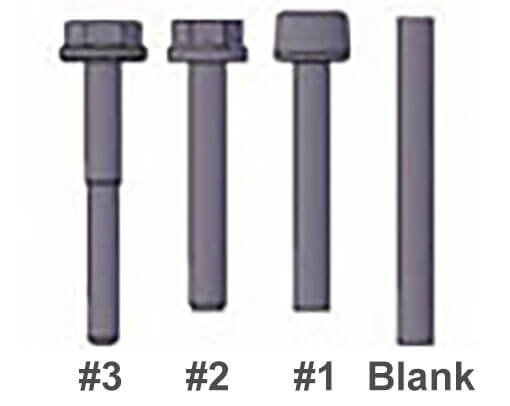

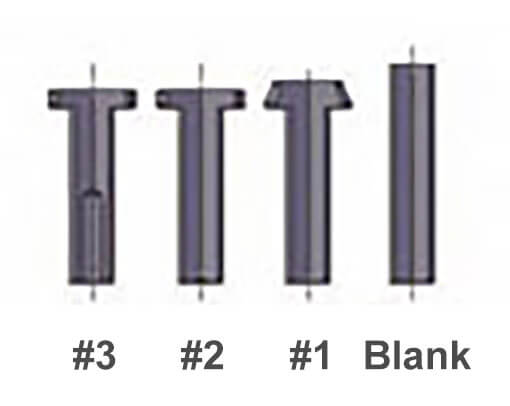

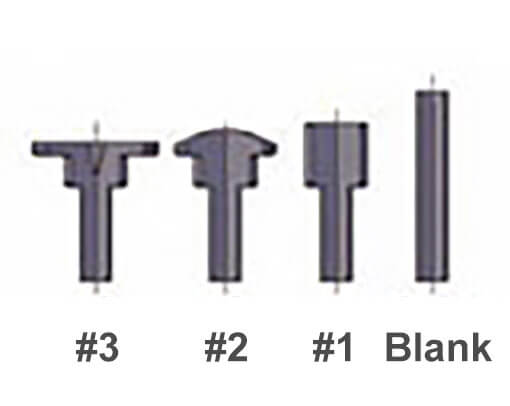

- Product Samples

Features

-

A.BF10B-3SFEEDING & CUT OFF MECHANISM:

A.BF10B-3SFEEDING & CUT OFF MECHANISM:Technical feeder to control the length of feeder is accurate & smooth, it helps feeder’s gear last longer. S-Cam cut off is the same as the center line of main shaft, can bear more force.

-

B.BF24B-3STRANSFER MECHANISM:

B.BF24B-3STRANSFER MECHANISM:The reciprocal motion of the finger is guided by both bevel gear and conjugate cam. (or single cam).

-

C.BF13B-3STRANSFER FINGER MECHANISM:

C.BF13B-3STRANSFER FINGER MECHANISM:Spring type transfer system to control the clamping motion will transfer the blank to each station steadily and precisely.

-

D.BF17B-3SP.L.C ELECTRICAL CONTROL:

D.BF17B-3SP.L.C ELECTRICAL CONTROL:Spring type transfer system to control the clamping motion will transfer the blank to each station steadily and precisely.

-

E. TRANSMISSION MECHANISM:

E. TRANSMISSION MECHANISM:4/8 (6) pole A-C main motor with 3 step gear box and it could provide total 6 different production speed. (total 6 step speed)

-

F.BF13B-3SMAIN SLIDE & P.K.O SYSTEM:

F.BF13B-3SMAIN SLIDE & P.K.O SYSTEM:Easy in punch adjusting, also can be adjusted the timing of punch position forward or backward which is based on customer’s need.

Specification

| SPECIFICATION MODEL(7B~17B) | BF7B-3S | BF10B-3S | BF13B-3S | BF13B-3SL | BF17B-3S |

|---|---|---|---|---|---|

| FORGING STATION | 3 | 3 | 3 | 3 | 3 |

| CUT-OFF DIA(MAX)(MM) | 5 | 8 | 10 | 10 | 12 |

| CUT-OFF LENGTH(MAX)(MM) | 55 | 70 | 94 | 130 | 105 |

| KICK-OUT LENGTH(MAX)(MM) | 45 | 55 | 70 | 115 | 80 |

| PUNCH KICK-OUT LENGTH(MAX)(MM) | 10 | 12 | 16 | 30 | 20 |

| CUT-OFF QUILL (DIA x LENGTH)(MM) | 20 x 30 | 28 x 46 | 35 x 56 | 38 x 79 | 40 x 66 |

| MAIN DIE (DIA x LENGTH)(MM) | 38 x 60 | 50 x 65 | 60 x 85 | 70 x 135 | 70 x 95 |

| CENTER DISTANCE BETWEEN DIES(MM) | 48 | 60 | 87 | 87 | 93 |

| PUNCH HOLE (DIA x LENGTH)(MM) | 32 x 60 | 40 x77 | 45 x 87 | 45 x 111 | 50 x 102 |

| RAM STROKE(MM) | 100 | 120 | 140 | 200 | 160 |

| FORGING POWER(TON) | 15 | 20 | 40 | 50 | 70 |

| PRODUCTS | 3/16"(M4) | 1/4"(M6) | 5/16"(M8) | 5/16"(M8) | 3/8"(M10) |

| OUTPUT PCS/MINUTE(MAX) | 300 | 250 | 210 | 180 | 180 |

| MAIN MOTOR(HP) | 7 ½ | 10 | 15 | 20 | 20 |

| LUBRICATION MOTOR(HP) | 1 | 1 | 1 | 1 | 1 |

| COOLING MOTOR(HP) | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 |

| LUBRICATION(L) | 120 | 120 | 180 | 180 | 200 |

| COOLANT(L) | 180 | 180 | 220 | 220 | 300 |

| APPROX.WT(KG) | 3500 | 6500 | 9000 | 13000 | 13000 |

| SPECIFICATION MODEL(17B~19B) | BF17B-3SL | BF17B3-SUL | BF19B-3S | BF19B-3SXL | BF19B-3SUL |

|---|---|---|---|---|---|

| FORGING STATION | 3 | 3 | 3 | 3 | 3 |

| CUT-OFF DIA(MAX)(MM) | 12 | 12 | 16 | 18 | 18 |

| CUT-OFF LENGTH(MAX)(MM) | 180 | 350 | 140 | 240 | 350 |

| KICK-OUT LENGTH(MAX)(MM) | 175 | 310 | 105 | 230 | 310 |

| PUNCH KICK-OUT LENGTH(MAX)(MM) | 35 | 40 | 25 | 40 | 60 |

| CUT-OFF QUILL (DIA x LENGTH)(MM) | 40 x 80 | 40x100 | 46x80 | 46x80 | 65x110 |

| MAIN DIE (DIA x LENGTH)(MM) | 80 x 185 | 80x330 | 80x123 | 93x240 | 93x350 |

| CENTER DISTANCE BETWEEN DIES(MM) | 93 | 93 | 114 | 114 | 114 |

| PUNCH HOLE (DIA x LENGTH)(MM) | 50 x 132 | 50x200 | 60x121 | 60x200 | 65x192 |

| RAM STROKE(MM) | 250 | 460 | 200 | 340 | 460 |

| FORGING POWER(TON) | 75 | 80 | 100 | 120 | 160 |

| PRODUCTS | 3/8"(M10) | 3/8"(M10) | 1/2"(M12) | 1/2"(M12) | 1/2"(M12) |

| OUTPUT PCS/MINUTE(MAX) | 150 | 70 | 150 | 115 | 70 |

| MAIN MOTOR(HP) | 30 | 40 | 40 | 50 | 75 |

| LUBRICATION MOTOR(HP) | 1 | 1 | 1 | 2 | 2 |

| COOLING MOTOR(HP) | 1/2 | 1/2 | 1/2 | 1 | 1 |

| LUBRICATION(L) | 200 | 350 | 300 | 325 | 500 |

| COOLANT(L) | 300 | 450 | 400 | 450 | 600 |

| APPROX.WT(KG) | 18000 | 26500 | 20000 | 35000 | 43000 |

| SPECIFICATION MODEL(24B~50B) | BF24B-3S | BF30B-3S | BF30B-3SXL | BF36B-3S | BF41B-3S | BF50B-3S |

|---|---|---|---|---|---|---|

| FORGING STATION | 3 | 3 | 3 | 3 | 3 | 3 |

| CUT-OFF DIA(MAX)(MM) | 20 | 24 | 24 | 29 | 29 | 44 |

| CUT-OFF LENGTH(MAX)(MM) | 185 | 260 | 430 | 260 | 320 | 380 |

| KICK-OUT LENGTH(MAX)(MM) | 175 | 220 | 400 | 220 | 280 | 360 |

| PUNCH KICK-OUT LENGTH(MAX)(MM) | 30 | 35 | 60 | 35 | 60 | 60 |

| CUT-OFF QUILL (DIA x LENGTH)(MM) | 60x100 | 75x120 | 75x120 | 90x140 | 115x140 | 138x165 |

| MAIN DIE (DIA x LENGTH)(MM) | 100x190 | 125x240 | 125x430 | 160x240 | 175x294 | 230x390 |

| CENTER DISTANCE BETWEEN DIES(MM) | 126 | 138 | 138 | 174 | 195 | 240 |

| PUNCH HOLE (DIA x LENGTH)(MM) | 75x185 | 90x197 | 95x250 | 105x197 | 130x232 | 146x245 |

| RAM STROKE(MM) | 280 | 360 | 560 | 360 | 440 | 520 |

| FORGING POWER(TON) | 160 | 220 | 360 | 320 | 500 | 800 |

| PRODUCTS | 5/8"(M16) | 3/4"(M20) | 3/4"(M20) | 1"(M24) | 1-1/8"(M27) | 1-1/2"(M36) |

| OUTPUT PCS/MINUTE(MAX) | 100 | 80 | 60 | 70 | 60 | 45 |

| MAIN MOTOR(HP) | 75 | 100 | 125 | 125 | 150 | 200 |

| LUBRICATION MOTOR(HP) | 2 | 2 | 2 | 2 | 2x2 | 2x2 |

| COOLING MOTOR(HP) | 1 | 1 | 1 | 1 | 1 | 1 |

| LUBRICATION(L) | 400 | 400 | 600 | 500 | 500 | 800 |

| COOLANT(L) | 500 | 500 | 600 | 600 | 600 | 800 |

| APPROX.WT(KG) | 43000 | 58000 | 84000 | 66000 | 120000 | 180000 |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.