5 STATION / 6 STATION NUT SPECIAL PARTS FORMER NP-SERIES

- Features

- Specification

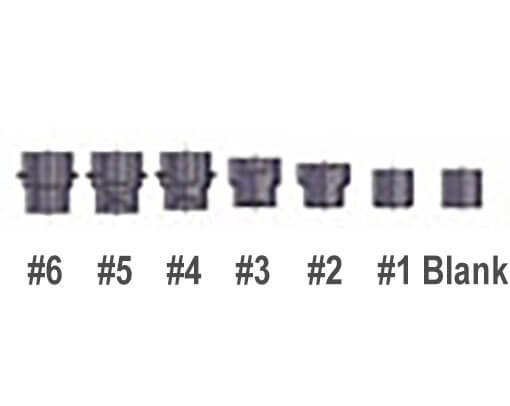

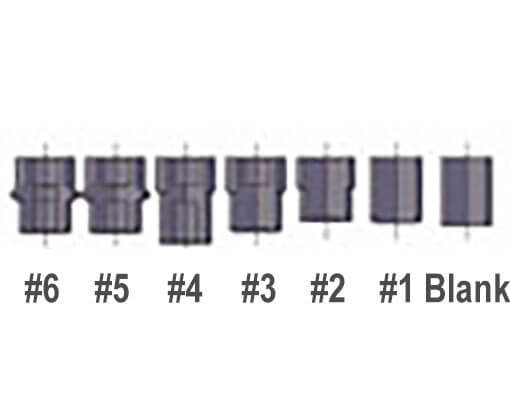

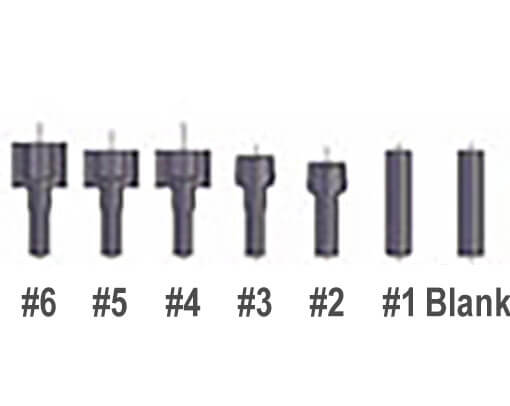

- Product Samples

- Video

Features

-

A. NP24B-6STRANSFER CHUCK FINGER MECHANISM:

A. NP24B-6STRANSFER CHUCK FINGER MECHANISM:Pneumatic cylinder device with rotation type chuck finger is more flexible in producing. With this system, the chuck finger enables to turn 180° or not.

-

B. NP24B-6SKICK-OUT MECHANISM:

B. NP24B-6SKICK-OUT MECHANISM:According to customer’s need, K.O. length position can be adjusted by hand wheel system or motor control. (Optional)

-

C. NP24B-6S

C. NP24B-6SAccording to customer’s need, feed length can be adjusted by the servo motor adjusting system. (Optional)

-

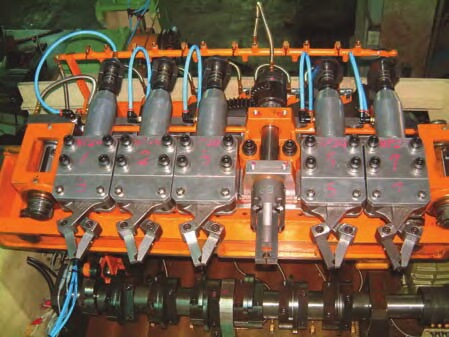

D. NP24B-6STRANSFER MECHANISM:

D. NP24B-6STRANSFER MECHANISM:The reciprocal motion of the finger is guided by both bevel gear and conjugate cam. (or single cam) Power ring assures firmly connected between conjugate cam & transmission shaft, with safety device to prevent any damage when accident happens.

-

E. NP24B-6SAIR CLUTCH / BRAKE SYSTEM:

E. NP24B-6SAIR CLUTCH / BRAKE SYSTEM:In part former is equipped with air clutch and air brake system, so no need to restart the power repeatedly during the running test.

-

F. NP24B-6SOVER ARM MAIN SLIDE & P.K.O SYSTEM:

F. NP24B-6SOVER ARM MAIN SLIDE & P.K.O SYSTEM:In forging long shank parts or high precision parts production, with this system to increasing the stable condition in producing.

Specification

| SPECIFICATION MODEL(10B~19B) | NP10B-6S | NP11B-6S | NP13B-5S | NP13B-6S | NP19B-5S |

|---|---|---|---|---|---|

| FORGING STATION | 6 | 6 | 5 | 6 | 5 |

| CUT-OFF DIA(MAX)(MM) | 12 | 16 | 16 | 18 | 20 |

| CUT-OFF LENGTH(MAX)(MM) | 50 | 60 | 60 | 60 | 60 |

| KICK-OUT LENGTH(MAX)(MM) | 50(20) | 70(30) | 70(30) | 70(30) | 70(30) |

| PUNCH KICK-OUT LENGTH(MAX)(MM) | 12 | 16 | 16 | 16 | 16 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 28x46 | 46x80 | 46x80 | 46x80 | 46x80 |

| MAIN DIE (DIA x LENGTH)(MM) | 50x65 | 60x110 | 70x110 | 70x110 | 100x110 |

| CENTER DISTANCE BETWEEN DIES (MM) | 60 | 75 | 87 | 87 | 114 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 40x77 | 45x90 | 50x90 | 50x90 | 50x90 |

| RAM STROKE(MM) | 120 | 140 | 140 | 140 | 140 |

| FORGING POWER(TON) | 60 | 100 | 100 | 135 | 160 |

| OUTPUT PCS/MINUTE(MAX) | 160 | 130 | 130 | 130 | 110 |

| MAIN MOTOR(HP) | 30 | 30 | 30 | 40 | 50 |

| LUBRICATION MOTOR(HP) | 1 | 1 | 1 | 1 | 1 |

| COOLING MOTOR(HP) | 1 | 1 | 1 | 1 | 1 |

| LUBRICATION(L) | 200 | 200 | 200 | 350 | 350 |

| COOLANT(L) | 300 | 300 | 300 | 550 | 550 |

| APPROX.WT(KG) | 13000 | 18000 | 18000 | 23000 | 23000 |

| SPECIFICATION MODEL(19B~33B) | NP-19B-6S | NP24B-5S | NP-24B-6S | NP30B-6S | NP33B-6S |

|---|---|---|---|---|---|

| FORGING STATION | 6 | 5 | 6 | 6 | 6 |

| CUT-OFF DIA(MAX)(MM) | 24 | 24 | 26 | 29 | 34 |

| CUT-OFF LENGTH(MAX)(MM) | 70 | 70 | 80 | 100 | 150 |

| KICK-OUT LENGTH(MAX)(MM) | 100(50) | 100(50) | 125(60) | 125(80) | 150(80) |

| PUNCH KICK-OUT LENGTH(MAX)(MM) | 30 | 30 | 30 | 40 | 45 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 70x75 | 70x75 | 85x90 | 95x100 | 110x155 |

| MAIN DIE (DIA x LENGTH)(MM) | 100x140 | 110x140 | 110x160 | 125x190 | 145x220 |

| CENTER DISTANCE BETWEEN DIES (MM) | 114 | 126 | 126 | 138 | 156 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 75x122 | 75x122 | 75x155 | 90x200 | 110x220 |

| RAM STROKE(MM) | 160 | 160 | 200 | 240 | 280 |

| FORGING POWER(TON) | 220 | 270 | 300 | 420 | 520 |

| OUTPUT PCS/MINUTE(MAX) | 110 | 90 | 90 | 70 | 60 |

| MAIN MOTOR(HP) | 75 | 100 | 100 | 125 | 150 |

| LUBRICATION MOTOR(HP) | 2 | 2 | 2 | 2 | 2x2 |

| COOLING MOTOR(HP) | 1 | 1 | 1 | 1 | 1 |

| LUBRICATION(L) | 550 | 550 | 700 | 750 | 1300 |

| COOLANT(L) | 800 | 800 | 900 | 900 | 1400 |

| APPROX.WT(KG) | 46000 | 46000 | 60000 | 85000 | 105000 |

| SPECIFICATION MODEL(36B~45B) | NP36B-5S | NP36B-6S | NP41B-5S | NP41B-6S | NP45B-5S |

|---|---|---|---|---|---|

| FORGING STATION | 5 | 6 | 5 | 6 | 5 |

| CUT-OFF DIA(MAX)(MM) | 34 | 41 | 41 | 44 | 44 |

| CUT-OFF LENGTH(MAX) (MM) | 150 | 150 | 150 | 150 | 150 |

| KICK-OUT LENGTH(MAX) (MM) | 150(80) | 150(80) | 150(80) | 160(80) | 160(80) |

| PUNCH KICK-OUT LENGTH(MAX) (MM) | 45 | 45 | 45 | 60 | 60 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 110x155 | 110x155 | 130x155 | 138x165 | 138x165 |

| MAIN DIE (DIA x LENGTH)(MM) | 163x220 | 150(163)x220 | 178x220 | 178x250 | 195x250 |

| CENTER DISTANCE BETWEEN DIES (MM) | 174 | 174 | 195 | 174 | 210 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 110x220 | 110x220 | 120x220 | 120x280 | 135x280 |

| RAM STROKE(MM) | 280 | 280 | 280 | 260 | 260 |

| FORGING POWER(TON) | 560 | 620 | 620 | 750 | 750 |

| OUTPUT PCS/MINUTE(MAX) | 60 | 60 | 55 | 55 | 60 |

| MAIN MOTOR(HP) | 150 | 150 | 150 | 200 | 200 |

| LUBRICATION MOTOR(HP) | 2x2 | 2x2 | 2x2 | 2x2 | 2x2 |

| COOLING MOTOR(HP) | 1 | 1 | 1 | 1 | 1 |

| LUBRICATION(L) | 1300 | 1400 | 1400 | 1500 | 1500 |

| COOLANT(L) | 1400 | 1500 | 1500 | 1600 | 1600 |

| APPROX.WT(KG) | 105000 | 140000 | 140000 | 180000 | 180000 |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.