5 STATION / 6 STATION SHORT PART FORMER PF-SERIES

- Features

- Specification

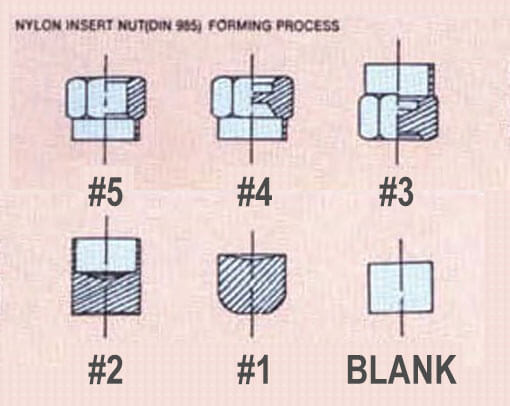

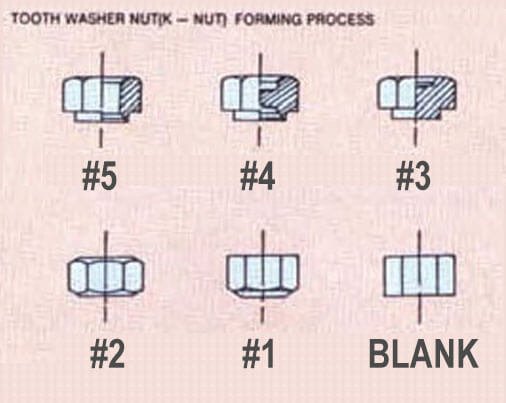

- Product Samples

Features

-

A. OVER ARM MAIN SLIDE:

A. OVER ARM MAIN SLIDE:All PF series models use an Over Arm main slide which increases the stability during formation process, and the P.K.O. system that allows more varieties of products to be produced.

-

B. TRANSFER FEEDING MECHINISM:

B. TRANSFER FEEDING MECHINISM:The transfer mechanism includes the I-style pneumatic clamp, nut former style rotating transfer mechanism, and the fingers are capable of opening and closing; these allow larger head size products to be produced. The rotating transfer stations can also

-

C. CUTTER MECHANISM:

C. CUTTER MECHANISM:The round closed cutter mechanism allows a smoother cut on the material surface.

-

D. TRANSFER STATION TRANSMISSION:

D. TRANSFER STATION TRANSMISSION:Transfer station's transmission has moved to the cutter's side, allowing the operator to be closer to the machine to make operations more convenient.

-

PF45B-6S

PF45B-6S -

PF15B5S

PF15B5S

Specification

| SPECIFICATION MODEL | PF8B-5S | PF8B-6S | PF11B-5S | PF13B-6S | PF15B-5S |

|---|---|---|---|---|---|

| FORGING STATION | 5 | 6 | 5 | 6 | 5 |

| CUT-OFF DIA(MAX)(MM) | 8 | 11 | 11 | 15 | 15 |

| CUT-OFF LENGTH(MAX)(MM) | 12 | 18 | 18 | 35 | 35 |

| CUTTER TYPE | OPEN TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE |

| TRANSFER TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE |

| K.O LENGTH (MM) | 16 | 30 | 30 | 42 | 42 |

| P.K.O(DIA x LENGTH) (MM) | 8 | 8 | 10 | 20 | 20 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 36x60 | 35x56 | 35x56 | 46x80 | 46x80 |

| MAIN DIE(DIA x LENGTH)(MM) | 37x42 | 37x70 | 45x70 | 55x90 | 65x90 |

| CENTER DISTANCE BETWEEN DIES | 37 | 37 | 45 | 55 | 65 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 25x67 | 25x67 | 30x80 | 40x90 | 40x90 |

| RAM STROKE(MM) | 75 | 90 | 90 | 185 | 185 |

| FORGING POWER(TON) | 30 | 60 | 60 | 100 | 100 |

| OUTPUT PCS/MINUTE(MAX) | 200 | 170 | 170 | 150 | 150 |

| MAIN MOTOR(HP) | 15 | 20 | 20 | 30 | 30 |

| APPROX.WT(KG) | 6000 | 8000 | 8000 | 14000 | 14000 |

| SPECIFICATION MODEL(17B~28B) | PF17B-6S | PF19B-5S | PF21B-6S | PF25B-5S | PF28B-6S |

|---|---|---|---|---|---|

| FORGING STATION | 6 | 5 | 6 | 5 | 6 |

| CUT-OFF DIA(MAX)(MM) | 19 | 19 | 24 | 24 | 32 |

| CUT-OFF LENGTH(MAX)(MM) | 50 | 50 | 70 | 70 | 100 |

| CUTTER TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE |

| TRANSFER TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE |

| K.O LENGTH (MM) | 70 | 70 | 80 | 80 | 120 |

| P.K.O(DIA x LENGTH) (MM) | 25 | 25 | 30 | 30 | 35 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 70x75 | 70x75 | 80x90 | 80x90 | 95x100 |

| MAIN DIE(DIA x LENGTH)(MM) | 72x72 | 80x72 | 93x110 | 114x110 | 120x160 |

| CENTER DISTANCE BETWEEN DIES | 72 | 80 | 93 | 114 | 120 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 42x120 | 48x120 | 60x120 | 75x122 | 75x155 |

| RAM STROKE(MM) | 200 | 200 | 240 | 240 | 250 |

| FORGING POWER(TON) | 165 | 165 | 250 | 250 | 460 |

| OUTPUT PCS/MINUTE(MAX) | 100 | 100 | 90 | 90 | 70 |

| MAIN MOTOR(HP) | 50 | 50 | 100 | 100 | 150 |

| APPROX.WT(KG) | 23000 | 23000 | 42000 | 42000 | 66000 |

| SPECIFICATION MODEL(36B~55B) | PF36B-5S | PF36B-6S | PF45B-5S | PF45B-6S | PF55B-5S |

|---|---|---|---|---|---|

| FORGING STATION | 5 | 6 | 5 | 6 | 5 |

| CUT-OFF DIA(MAX)(MM) | 32 | 36 | 36 | 45 | 45 |

| CUT-OFF LENGTH(MAX)(MM) | 100 | 150 | 150 | 150 | 150 |

| CUTTER TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE |

| TRANSFER TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE |

| K.O LENGTH (MM) | 120 | 120 | 120 | 130 | 130 |

| P.K.O(DIA x LENGTH) (MM) | 35 | 40 | 40 | 50 | 50 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 95x100 | 110x155 | 110x155 | 132x155 | 132x155 |

| MAIN DIE(DIA x LENGTH)(MM) | 156x160 | 156x220 | 195x220 | 195x330 | 235x330 |

| CENTER DISTANCE BETWEEN DIES | 156 | 156 | 195 | 195 | 235 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 110x155 | 110x220 | 120x220 | 120x312 | 135x312 |

| RAM STROKE(MM) | 250 | 260 | 260 | 260 | 260 |

| FORGING POWER(TON) | 460 | 600 | 600 | 900 | 900 |

| OUTPUT PCS/MINUTE(MAX) | 70 | 55 | 55 | 45 | 45 |

| MAIN MOTOR(HP) | 150 | 175 | 175 | 300 | 300 |

| APPROX.WT(KG) | 66000 | 105000 | 105000 | 180000 | 180000 |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.